Introduction to Bourbon

At ANGEL’S ENVY, we’re committed to honoring the tradition of whiskey, whilst embracing progress. From modern twists on classic bourbon cocktails to innovating our whiskey to create unique blends that are reminiscent of the classics whilst taking on a whole new tasting level to the bourbon game. We aren’t afraid to improve tradition – and you shouldn’t be either!

With expert craftsmanship and a desire to continuously improve, ANGEL’S ENVY Bourbon pushes boundaries. Whether you’re new to bourbon or a whiskey connoisseur, we’ve got you covered.

What is Bourbon?

Bourbon is a type of American whiskey made mainly from corn. Bourbon has several key characteristics that it has to have to earn its title and having a grain composition that is at least 51% corn is one of them, as well as not exceeding 80% alcohol by volume during distillation and aging in new charred oak barrels.

But, what does all this mean and how is bourbon made? After the ingredients for the bourbon have been ground, mashed, and fermented (we won’t bore you with all the technicals), the resulting liquid known as ‘wash’ is distilled. The distillation process is essentially converting a liquid into vapor and back again to separate and remove impurities from the alcohol, this is usually done twice and creates a clear, very strong spirit. Next, the key to good bourbon is the aging process, the distilled liquid is placed into charred oak barrels, and the length of time the bourbon ages will define its color, taste, and aroma. There is no minimum amount of time a bourbon must be aged, but to qualify as straight bourbon it needs to be at least four years.

Barrel storage is another key part of the bourbon creation process, changes in temperature cause interactions with the wood that also contribute to a bourbon’s color and flavor. After achieving the desired result from the aging process, the spirit is then filtered and diluted to the desired alcohol content and bottled.

A great way to introduce yourself as a beginner of bourbon is to try bourbon-based cocktails, this allows you to get used to the taste and effects of the alcohol. Bourbon is a great introduction to the world of alcohol as its versatility allows it to be enjoyed in countless ways, so there’s something for everyone to enjoy.

The Story of Bourbon

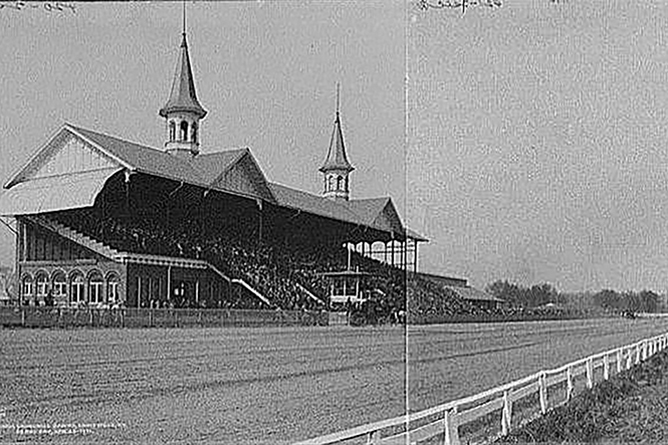

With deep roots in American history, bourbon is traced back to the colonial era. This is due to the abundance of corn in the late 18th century and therefore it became a primary ingredient in distilled spirits. Following the Whiskey Rebellion (opposing the new tax rule on distilled spirits), many whiskey producers migrated to Kentucky due to its fertile soil aiding grain production and most whiskey is still made in Kentucky today.

Whiskey distilleries began growing during this period, particularly post-civil war as distribution became easier, as did the introduction of charred oak barrels. Then we get to the 1920s and Prohibition, forcing many distilleries to close, whilst others opted to make medicinal whiskey. After the 1933 repeal, bourbon saw a resurgence (no surprises there) and the modern bourbon era was born.

Fast forward to today and bourbon is drank and enjoyed worldwide. From a diverse range of whiskey cocktails on bars across the globe to a bottle of bourbon being commonplace in the home for entertaining or a relaxing drink.

Ways To Enjoy Bourbon

“There is no one-size-fits-all approach when it comes to enjoying bourbon – and that’s the beauty of it. This versatile spirit can be enjoyed as a base for cocktails, with a few drops of water, or neat. Our range of whiskey at ANGEL’S ENVY features a variety of finishes contributing to an array of flavors to be enjoyed in a multitude of ways.

To truly appreciate the handiwork and taste of bourbon you can enjoy your drink on the rocks (over ice), but bourbon can also be used in cooking, particularly with meats or desserts.

The Smell

There will be slight variations depending on the type of bourbon you choose and how it has been stored and aged, however, generally, bourbon will have a rich and sweet smell. As bourbon is aged in charred oak barrels, these oak notes come through providing a woody and almost smoky aroma. Bourbon is a complex drink with multiple sensory layers to enjoy, so take a deep breath and take it all in.

The Look

Bourbon is varying degrees of amber in color, from pale or light to deep and dark. This is all determined by the aging process. Bourbon is clear with no sediment or bits, it’s a smooth spirit that allows you to appreciate the hues of color.

The Taste

Again, this will differ with the subtleties of various ingredients, but in general, bourbon will taste smooth and balanced, a harmonious mix of flavors. Varying degrees of sweetness, spice, and citrus will all depend on aging, distillation, and ingredients. But with ANGEL’S ENVY, you can always count on a full-bodied and rich taste, that is consistent with every sip.”

Visit Our Distillery

Take your journey into the world of bourbon one step further with our distillery tour. This fully immersive experience includes putting you behind the bar, cocktail classes, and a guided, insider’s tour of our fully operational urban Main Street distillery. Learn all about the whiskey-making process and ask questions with similar-minded bourbon lovers.

No matter how you enjoy your bourbon, we have a whiskey for you. Check out our online store and find your nearest stockist of ANGEL’S ENVY.